That said, I have a lot of projects going. Here is what is on the desk, and, hopefully, will be done some day.

The Arch Roof building, with clear side walls. I plan on making this in to a machine shop with complete interior.

A test assembly. One of the prints failed, and I made a quick diorama from the junk, a-couple-small-dioramas-using-failed-3d

The upper walls are 3d printed in clear ABS, so the trusses, also 3d printed, can be seen when back lit. The windows and doors are from Tichy.

If you have followed my blog for any time, you know I like the vintage kits. This is one one I have never seen before.

A spun aluminum tank, something you won't see today.

The plans...

I am missing the separate water spout, and I have not found one I like yet, so this project is getting ready to move to the back burner.

The plans...

I am missing the separate water spout, and I have not found one I like yet, so this project is getting ready to move to the back burner.

I picked this up to use as a water tank for the M of W department. It weighs a ton! Lettering and a lot of rust and weathering to do.

Ahhhh, the hog farm. I have been working on this, on and off, for well over a year. I have not put it back together since I took it to the last show, as you can see, it looks like an earth quake hit. I am not a fan of scenery, so I have been putting off finishing this for months. I think the only thing I have to do is the hog pen, and some final weathering. Most of the buildings I designed and 3d printed, along with several that are Woodland Scenics metal kits. Here is a link to a complete list of the structures/blog entries so far. down-on-farm-post-listing

A bit of a complicated 3d printed structure, but I love gas stations. This one is based on several drawings I have, but mostly the one below. I keep adding details, currently working on the interior.

This is a Hot Wheels Dodge Airflow tanker based on a 1939 design. Although most Hot Wheels are about 1/64 scale, the larger items, because they are scaled to fit the packaging, sometime come out to close to HO scale. This actually has a wheel base slightly smaller than HO scale. I am going to have to grit blast it to get it clean enough to paint, and I am still searching for wheels and tires that look right.

The prototype, although I won't be doing mine in Texaco.

This is one of those "I have no idea why I am doing this" projects. It is a steam launch, scratch built, a basic shell from the junk box, styrene strip upper frame, and some 3d printed parts...so far.

Mine is freelanced from several pictures and plans.

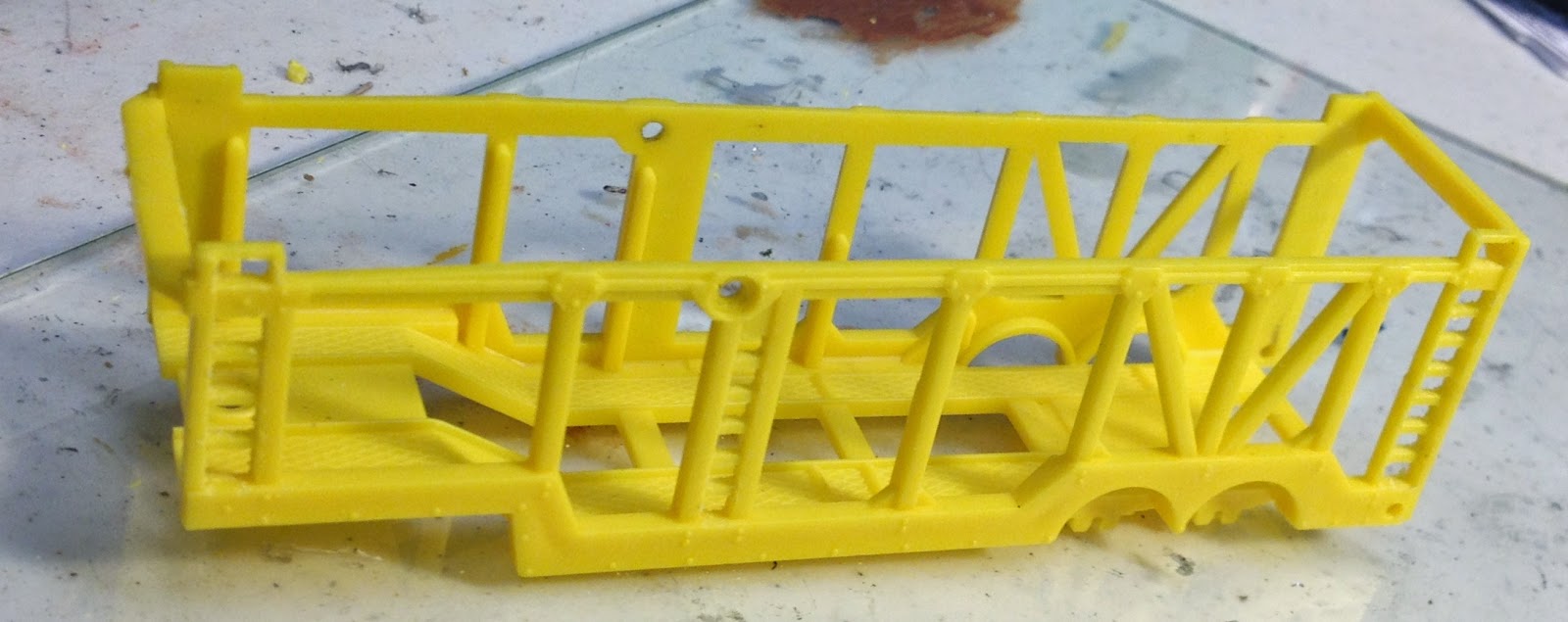

Another of those vintage kits. This one a flanger kitbash from Roundhouse. Mostly painting to do, which was put off due to the winter.

AND now, the modeling item that has been taking the most of my time of late, the Turkey Creek NMRA division modeling challenge "kit". This a wood structure designed, cut on a Cricut and the part assembled by some of the members. Here are some progress shots.

In the end, this project will warrant it's own blog entry.

There is actually more than this, but that is enough to keep me busy. Hopefully will get the bathroom ready for the tile man this week.