Here is how I have arranged the layout at this time.

Givens

1. It is 1949.

2. HO scale standard gauge main line.

3. Line runs from North Staging (KC) to Car Ferry Dock at Van Buren, AR.

4. Within reason, modular specifications to meet Free-Mo standards

a. http://www.free-mo.org/standard/

b. 42” minimum radius on the main line

c. #8 Turnouts on the main line

5. Main cities of Joplin, MO & Springdale, AR.

6. The town of Splitlog must be represented.

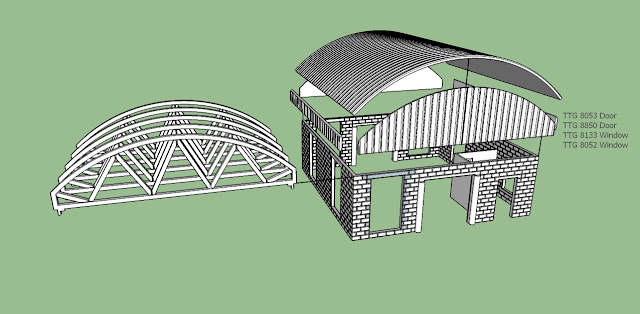

7. 3’ narrow gauge line (Trees Unlimited) somewhere south of Springdale a. associated with a large sawmill.

8. 30” narrow gauge somewhere

9. 18” operating mine railroad

10.Interchanges:

a. ATSF, MKT, KCS, MoPac & Frisco in Joplin.

b. Frisco in Springdale

c. MoPac, KCS, Frisco in Van Buren

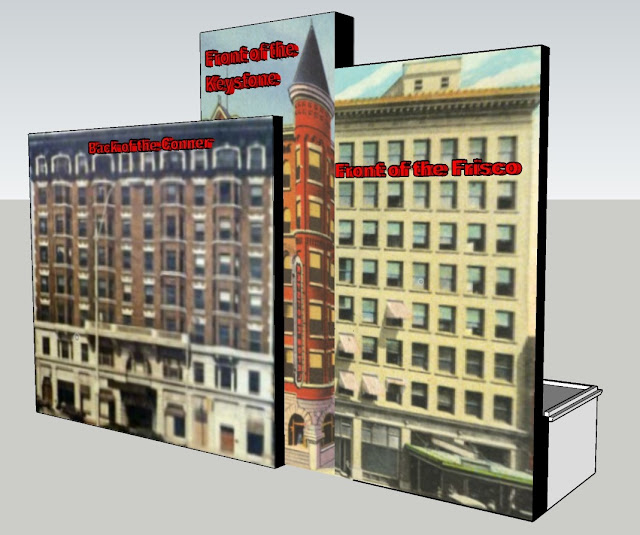

11.Joplin Union Station will be massively compressed, flat on the back with taller building flats attached to the back. I will have to do a drawing to make that make any since.

Druthers

1. Gulf Oil refinery somewhere south of Joplin.

2. 36” aisles

The layout sections are 26' in depth except for at Van Buren where it is 33". Almost all section of the layout can be operated from both sides. The only exceptions are this time are Joplin and the section with the large sawmill. The concept for those two sections are shown below.

The station and hotels will sit where indicated. The Joplin station track side will have some depth to it, but the hotels will be flats. I will have to get an artist to draw the hotels, as pictures of the back of the hotels are sketchy or non-existent. I plan on mounting the hotel drawings on black foam core to give them some semblance of depth. The total depth, as currently planned, will be about 6", and the length will be somewhat longer the 12", and about 7" tall. The dark blue is the main line, and the light blue are passing sidings.

.JPG)