I needed a barn for my little hog farm, and I always like the round barns. They are kind of an oddity, but when I lived in the Joplin area, there was one in the neighboring village of Saginaw I used to drive by on a regular basis.

I pulled this image of the barn in Saginaw, MO from Pinterest on the web, but could not fine out who took the picture.

Carolina Craftsman Kits, http://carolinacraftsmankits.com/store/, makes a great laser cut wood kit based on a round barn in Vermont. It has a foot print of 9" x 11", which is almost a quarter of the area I planned for my diorama.

The Vermont Barn from Carolina Craftsman Kits. (Picture from their web site)

The direct link to the kit: http://carolinacraftsmankits.com/store/index.php?main_page=product_info&cPath=1&products_id=36

I needed a much smaller barn, say in the 4-5" range. Since I had already done some lap siding, I knew that the siding, and making in round, hexagon, or Octagon would not be a problem to print, but I thought the vent on the top would take a few attempts, and it did.

I am not totally happy with what I ended up with, but it is acceptable to me. I would have liked to have open, see through, vents, but that is just not possible with the 3d printer technology I am using. At least not in this small scale.

Here is the final plan, exploded for printing, not including the foundation.

Due to its size, relative to my printer, I printed the barn in six sections: the walls, the cupola, the doors and windows, the roof, the foundation, and after it the project was just about done, I add the finale.

I test fit everything together once I got all the major pieces printed. In this picture, you can see the foundation has been primed, and the walls have their first coat of red paint. At this point, I decided I did not like the proportions, I wanted it taller. Rather than reprinting the walls, or adding to them, I decided to add to the foundation. Thus making the door, FWIW, 11' tall. The barn is about 4" across, or about 30' in HO scale.

I did not want the barn to be on plain concrete blocks, I have done that, and am always looking to try something different. I went for a cut stone look. All the stones are 8" tall, but of varying lengths. To add texture to the surface, I added a stucco paint that I found at Michaels Crafts, in the Martha Stewart craft paints section.

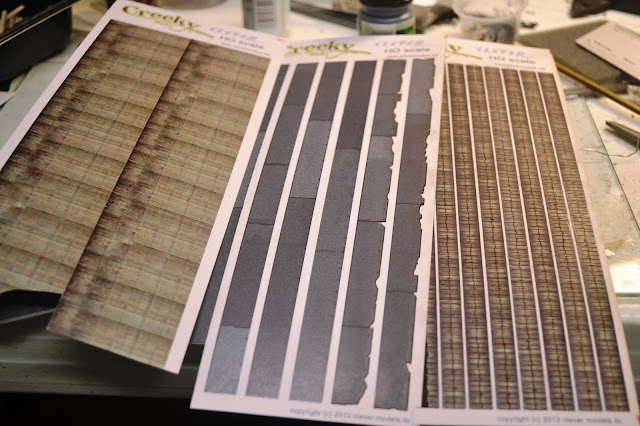

As I said, I am always looking to try something new, so in that vain, every once in a while, I walk around Micheals Crafts looking for something I can use. I ran across this wrinkle paper in the scrap booking section, and nice gray, weathered wood color.

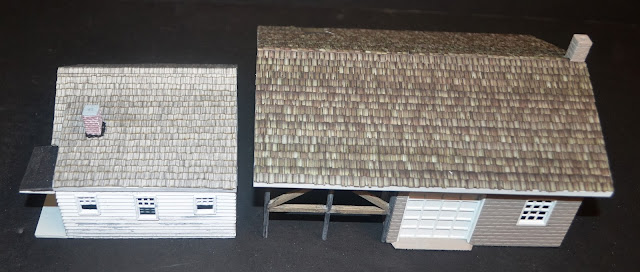

I cut it in to individual wood shingles, varying lengths and widths about 1/4" long and 1/16"- 1/8" wide. To say it took a long time to cut, align and glue all these in place would be an understatement. In the end, though, it looks pretty good.

I added the finale after seeing how difficult it was going to be to shingle the point. It was 3d printed, and then painted with Bronze from Sophisticated Finishes, and then a coat of the chemical they provide to patina the bronze. It is great stuff. I would like to add a weather vane before I finish up the diorama.

And if you have not seen the details from Vectorcuts.com, the you really need to check them out. These are from Vector cuts, and I hope I run in to them at a show, so I don't have to order them on-line.

The building is just set together, as I see no need to glue it together until I get ready to install in on the diorama. And I won't weather it until I weather all the building in the diorama at one time. The foundation was painted with several shades of brown and tan washed and a wash of A&I. Then a final wash of very thin white paint to fill in the mortar lines.

I modeled the doors on one side as hinged doors, and as sliders on the other side. The hinges are hinges I printed on the Afina 3d printer.

On the other side, I went with sliding doors. I will add bracing to the door track once I decide on the ground levels around the barn. At this point, I am planning on one side being at about grade, and the other will be showing about 2/3 of the ramp, but I need to talk to some old hog farmers to get the layout of the farm plausible. Anyone? Anyone? Bueller?

(http://www.youtube.com/watch?v=uhiCFdWeQfA)

The next blog post will probably be the wind mill and the tool shed for the farm, both Woodland Scenics kits. The rest of the structures I am planning for this diorama are:

Portable Hog Feeders, scratch built wood

Corn Crib from Blairline wood kit

Portable Hog barns, scratch built wood

Farrowing House, 3d printed

Speaking of Corn Cribs, anyone have any ideas on how to model ears of corn in HO scale? AND, I assume the that is stored and fed to the piggies has been removed from it's husk? I may need to model a hand crank corn shucker.

Previous posts in the Down on the Farm series: