Kansas City, Fort Smith & Gulf Railroad, The Splitlog Route

I am working on basic plans for a new layout, as soon as the new basement is available. A couple of points of interest: our previous home has not sold, the first sale fell through, so ground has not been broken on the new house yet.

Here are some plans I have sketched out, and a short list of "Givens & Druthers". All are subject to much editing over the next several month, and I am soliciting feedback. Lots of drawings to follow!

I will be posting a link to this in the NMRA Layout Design Special Interest Group, along with several other Social Media sites.

Here is an overall view of what I currently envision for the benchwork, along with a few dimensions. Click on the pictures to enlarge them.

And what might be the most important piece of information, the givens and druthers. I am sure there will be many additions over the next several months.

FCFS&G Givens and Druthers, 8.13.22

Givens

1. It is 1949.

2. HO scale standard gauge main line.

3. Line runs from North Staging (KC) to Car Ferry Dock at Van Buren, AR.

4. Within reason, modular specifications to meet Free-Mo standards

a. http://www.free-mo.org/standard/

b. 42” minimum radius on the main line

c. #8 Turnouts on the main line

5. Main cities of Joplin, MO & Springdale, AR.

6. The town of Splitlog must be represented.

7. 3’ narrow gauge line (Trees Unlimited) somewhere south of Springdale

a. associated with a large sawmill.

8. 30” narrow gauge somewhere

9. 18” operating mine railroad

10.Interchange with ATSF, MKT, KCS, MoPac & Frisco in Joplin.

a. ATSF & MKT would be minimal.

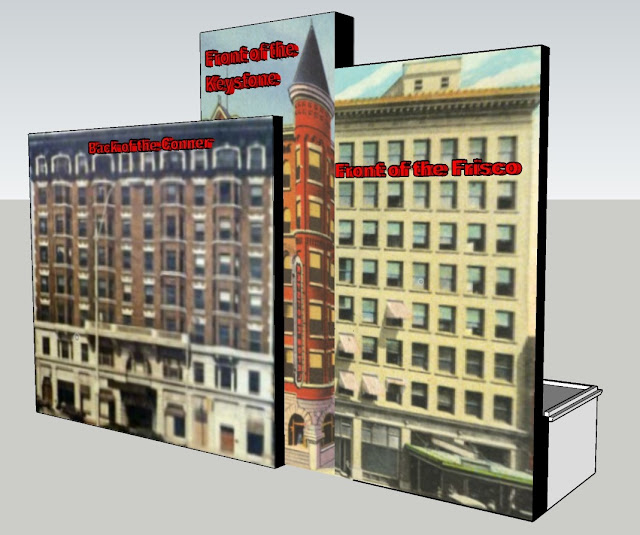

11.Joplin Union Station will be massively compressed, flat on the back with

taller building flats attached to the back. I will have to do a drawing to

make that make any since.

12.

13.

Druthers

1. Gulf Oil refinery somewhere south of Joplin.

2. 36” aisles

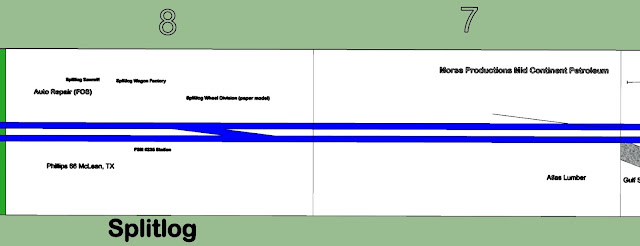

Here is the linear plan, but obviously it is not legible, so I have broke it down into small pieces. Each numbered section represents 4'.

This will obviously be backwards to some, as it is right to left. As currently planned, the bottom of this section would be the first thing you see as you come down the stairs. This is the north end, KC/staging. I am planning on some scenery even though, for the most part, this is staging. Dark blue is mainline trackage, and light blue is passing tracks. As this is very much a work in progress, siding may be colored or may just be a straight line.

8' of rural to industrial area between KC staging and Joplin. The benchwork also increases from 24" to 26" to accommodate double track mainline. You can click on the images and enlarge them. should you desire to do so. Dark blue is mainline trackage, and light blue is passing tracks.

Joplin. Union Station and some building flats associated with it will create somewhat of a view block. At the moment, this is the only view block on the layout, but that could change.

Section 7 is a city to rural transition, although I love structures and will probably fill all the space up. Section 8 is the small town of Splitlog, named after the patriarch of the railroad, Mathias Splitlog. A real person, and a real town. I will add some fictitious history in a later post.

As we leave Splitlog, we go through Woodyville, all Woodland Scenics small buildings, and to the Gulf Oil Refinery. I have narrowed this down to 24" wide at the refinery, and moved the mainline to one side to make more room for the refinery. I can see the need to keep this section wider, among other possible changes.

Springdale is a major city on the layout. I need to add Frisco interchange trackage. I kept the track to one side, the east, for what it's worth, to give more room for structures. I think I will add a long passing siding to the narrow side, probably going back to the refinery.

Now it get a little complicated. Somewhere in sections 13-16 I need to add a tunnel through the Boston Mountains. Sections 13 has the standard gauge mainline running along the east side and the mainline gets back to the center on section 14, The darker green areas is raised several inches and there will be a large on the plateau. How much it will be raised has yet to be determined. The dark orange track is the 3' gauge Trees Unlimited, and runs through the mountains for several sections. The light orange track is the ECH 18" mining line, and I am planning on running it under the mountain, but over the standard gauge mainline. We will see how that works out. The red trackage that starts in section 14 and continues south, is the J&N 30" gauge line hauling the Unobtainium mined by the ECH, and lumber from small mills along the line.

Section 15 and 16 are mountainous, with an uphill grade starting in 16 or 17 and ending at section 13. These sections will take hundreds and hundreds of oak and hickory trees. The multicolored brown stripe is the cliff between the mainline grade and the logging branch. The mainline will most likely be in a valley between the two narrow gauge lines.

Section 17 is the HOn3 interchange with the standard gauge. Section is rural and widens out to have a short passing siding.

Section 19 is the HOn30 interchange, and more rural industry, and section 20 is more industrial, and transitions into Van Buren.

Getting to the end, and I am looking at a couple of options. Here is the lineal plan, and my original idea. I was going to end it at the water front, and have a Frisco interchange. I am going to have multiple car barges that will serve as south end staging. As I got to laying out the benchwork in the basement plan, I realized I could put in a large reverse loop.

This certainly gives a lot more room for industries and scenery. 42" radius mainline fits on this and still has 12" to the outside. I still need the river and barge dock, but maybe I can find a way to add a representation of the Frisco bridge over the Arkansas river, and still get in a reverse loop.

|

It would seem that it would be idea to have a reverse loop at the south end and a turntable on the north end.

Feedback is welcome, but keep the Givens and Druthers in mind. |

Where is the KCFS&G? Some maps to hopefully help you orient yourself.

The KCFS&G runs from Joplin, in the southwest corner of Missouri, located in the Ozark Highlands Ecoregion, #39, through the Boston Mountains, #38, into the Arkansas Valley ecoregion, #37, where Van Buren and Fort Smith are located on the Arkansas River, nestled up against Oklahoma. Van Buren on the north side of the river, and Fort Smith on the south side.

.JPG)