A couple kitbashes of Mini-Lindy Ford Pickups

A shot of the two pickups, and the Packard as picked up of eBay.

A first test assembly with a dump bed I had in the parts bin. I posted this on the 1/87 scale vehicle Facebook page for some feedback, and got just what I wanted.

I filled in the hole in the center of the hood, and 3D printed a shorter bed.

This model was missing the front grill and bumper. I designed and 3D printed and new one. This was an early test, as I made some changes on the final assembly.

I 3D printed the frame, and made the dump bed so it would dump, although I never have found a way I liked to put a hydraulic cylinder on it.

Since the fans would be visible, I designed and printed several sizes in order to pick a size.

I fabricated the exhaust out of brass tubing.

This model was also missing the windows, so I 3D printed a form and vacuum formed the windows. The form is in the dump bed.

In this view you can see the rusted exhaust manifold, another part I designed and 3D printed.

Tow/Boom Truck

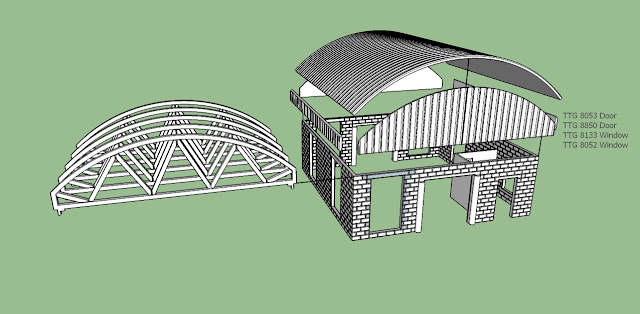

I wanted to turn the other truck into a two truck. In order to design the bed, I took straight on pictures of the truck, uploaded the pictures into SketchUp, and sized the pictures to scale.

I drew the basic design right over the photographs to get the correct curves and dimensions.

On this one, I closed in the entire top of the hood.

I also designed and printed the boom and headache rack.

I scratch built the winches