For custom details, Shapeways is the way to go. This assortment is all wall details. Some of these I had printed before, others, this is the first time. The set includes a lot of parts.

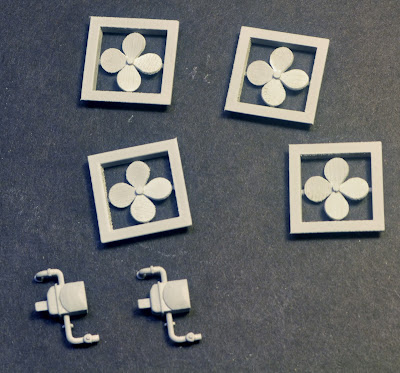

There are two different gas meters, two of each.

A selection of pipes to run along the walls.

Four different wall vents, four of each. Three of them are see through, the four smallest are surface mount.

Four wall fans, and two types of electric meters, four of each.

Roof drain scuppers.

Two types, eight of each. Four coal doors, a set of six mail boxes )note the raised lettering for the apartments). There are also two size of fire sprinkler connections, four of each. I have since added four alarm bells to put on the outside wall of the building.

There is a large selection of tension rod washers (sometimes called stars). Nine styles, eight of each.

Here are a few pictures of the tension rod washers. These are based on prototype pictures, and are used on most older masonry buildings. These are HO scale, so the are between 1/8" and 1/4" in size.

There are eight of each of the tension rod washers in the set.

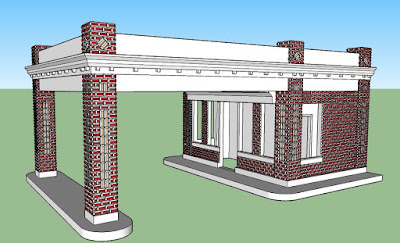

Here is one installed on a building, an old Roundhouse kit.

The smaller gas meter, and the piping.

Here is an example of how I used the pipe, and you can also see more of the tension washers.

Here are the larger gas meter, and four wall mount fans.

At the top of the picture are the fire alarm bells and the eight fire hose connections. Next down is the apartment mail boxes with raise lettering. And, at the bottom are the scupper (flat roof downspout drain), two styles.

Here is another shot of the mail boxes and fire apparatus. To the right are eight electric meters, four of two different styles. The connections can easily be filed off if needed.

The electric meters installed on an apartment building.

The mail boxes.

Sixteen vents, four sizes. The small vents to the right are surface mount, the rest are see through, i.e. real vents. You can see the copper penny through the vents. The coal doors are in the upper right.

I held the larger vent up to the light for this picture. One has to be very careful to not fill the vents up when painting.

I added a coal door to this apartment building.

Here are some links to other details I have designed and had printed at Shapeways.