This could be an extremely long post, as this is a very large set of tools with lots of details, so I will cover a very few machines at a time. This tool set, which is available on shapeway.com, is made up of 16 individual tools.

The set includes, from left to right, front to back...

Front Row: 1. Metal Shaper, 2. Horizontal Band Saw, 3. Small Metal Lathe, 4. Bench mount Grinder with 2" x 8" Wheels, 5. Pedestal mounted Bench Grinder, 6. Bench mount Grinder with 1" x 8" Wheels, 7. Floor Drill Press, 8. Radial Floor Drill Press, 9. Metal Lathe

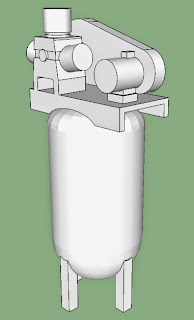

Back Row: 10. Large Vertical Milling Machine, 11. Smaller Vertical Milling Machine, 12. Horizontal Milling Machine, 13. Surface Grinder, 14. Vertical Band Saw, 15. Air Compressor, 14. Gas Welding Bottles on a Cart.

I am going to post the particulars on each items in the order I finished them up.

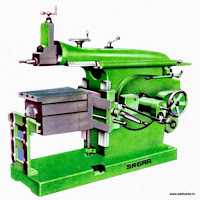

Metal Shaper

I used one of these back in the day; I am not sure they are even used much anymore. I am modeling 1949, so it will fit fine. When designing this as a generic model, I worked from several photographs and drawings.

The drawings and the pictures I worked from.

Here is the 3d printable drawing I came up with on my second try. This will be printed in a couple weeks, but the first try, with all it's issues is below.

My first try had several parts that were just barely over the minimum printable size, and as happens, some of those parts either did not print, or were broken in the cleaning or shipping process. There were some pieces in the plastic bags the part came in, so I could see some file pieces broke off in shipment. Given the fragile nature of these items, and the extremely small cross-sections on many of the parts, this is to be expected, in my opinion. For me it is okay, for selling the product to other, I will need to beef up the cross-sections on several parts to make them tougher.

Primed only, Note that all three of the wheels, cranks and handles on the top were broke off, yet the ones one the side all survived and were formed perfectly. The two vertical bars on the very front did not form, or were broken at some point. There are all issues that I fixed in the newest upload to shapeways.

For my purposes, the machine I recieved was fixable. I drilled out the block in the front an glued new round bars in place to raise and lower the table. They are the silver vertical bars at the front of the machine.

In this side view, you can see I added parts for the three missing pieces on top. A bit of wire, a Micro-Trains N scale brake wheel from Show Me Lines, and a piece of round plastic, and everything is good. As you can readily see in this view, the crank and wheel on this side formed fine, and were not damaged in shipping or handling.

Horizontal Bandsaw

Drawn from some pictures, because of some of the angles, it was a little bit of a pain to draw. I had needed to do several adjustments after the first print, as it was very fragile, and I broke it even handling it with tweezers. I increased the connection between the base and the band saw to make it stronger.

And looking at this drawing, even though it passed the Shapeways automated checks, I see several changes I need to make.

It is really small, so getting the details to show up, they generally have to be oversized.

I was able to get the wheels to form on the left end, and a handle on the right end. Not bad for the size.

Vertical Bandsaw

This I have done before, but I wanted on for the machine show, so I added it to this set. Although it looks small sitting on a penny, it scales out to a 30" saw, that is a big unit.

It would be suitable for both a metal or wood shop.

Next time I will cover three or four more tools.

Other posts featuring items 3d printed at Shapeways:

.jpg)